- Home

Our markets

Our markets

SONIMAT applies its expertise across a wide range of sectors, including aeronautics, agri-food, automotive, cosmetics, electronics, medical energy, plastics, and textiles, continually innovating in each.

SONIMAT applies its expertise across a wide range of sectors, including aeronautics, agri-food, automotive, cosmetics, electronics, medical energy, plastics, and textiles, continually innovating in each.

The automotive industry, the leading market for welding applications, plays a key role in SONIMAT’s development. Historically associated with ultrasonic welding, our teams have designed solid, fast and precise solutions for thermoplastic welding. Today, we master various processes to help you assemble your plastic parts: infrared, hot plate, laser, ultrasonic and spin welding.

The aerospace industry favours composite materials for their advantages: high rigidity, light weight, design flexibility and fatigue resistance. SONIMAT offers cutting and welding solutions for these materials (carbon-based composites, honeycomb, aluminium and Nomex) through its own product range (cutting effectors, portable equipment) and the development of customised machines.

Ultrasonic slicing offers perfect cutting quality for a wide range of food products, such as cheese, biscuits, fruit, cakes and mousses. Our processes guarantee thin slices of consistent thickness, and no product loss. In addition to food slicing, we also use ultrasound to hermetically seal packaging.

The cosmetics market, often associated with luxury, demands impeccable visual appeal. High-speed production for this mass-market requires proven, repeatable assembly solutions. Our ultrasonic welding solutions meet these criteria perfectly and require no additional materials or adhesives. This is a considerable advantage in the highly regulated cosmetics sector.

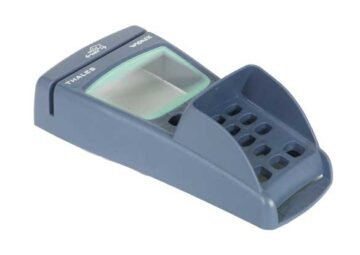

To meet the large-scale production needs of the electronics market, reliable and reproducible soldering solutions are essential. The machines we design are specially adapted to these requirements, thanks to our mastery of ultrasound.

Plastic is omnipresent in everyday objects. Most consumer products, such as toys, household equipment and office supplies, require an assembly stage. Our welding machines, designed to mass production, ensure precision and repeatability with optimal assembly quality.

Thermoplastic welding is everywhere in everyday objects. Our machines offer reliable welding solutions without the need for additional materials. Thanks to its expertise, SONIMAT is recognized for its standard and customized welding machines. We offer technologies adapted to the filtration industry: infrared, hot plate, ultrasonic, laser and spin and hot staking.

The sports and leisure industry has long utilised composite materials for their performance, rigidity and lightness. SONIMAT supports manufacturers and contractors in the finishing and assembly of composites, as well as thermoplastics, to produce sports products and equipment.

As experts in ultrasonic cutting and welding of composites, we offer the naval and nautical sectors solutions of superior precision and quality. Our mastery of ultrasound ensures efficiency and adaptability to the materials and specific needs of this market.

In the medical sector, compliance with safety and hygiene standards and robust welds are essential. Ultrasonic and laser welding technologies are the most common, but our hot blade, infrared and spin welding machines are also popular with medical equipment manufacturers.

Access all of our download resources