Our welding solutions for the electric vehicle industry

In the current energy transition context, the automotive industry is massively moving towards producing electric vehicles.

Plastics are becoming the first material for reducing vehicles’ weight, giving electric vehicles a greater range.

Our various welding technologies for plastic parts continue to play a major role in this market, particularly in the manufacture of parts and systems for battery cooling and heating parts, as well as electric motors.

Ultrasonic welding

Ultrasonic welding offers an optimal solution for the assembly of multi-path components essential for keeping appropriate operational temperatures, thanks to its ability to create joints with suitable sealing and strength.

Ultrasonic welding is energy-efficient, fast, and compatible with a wide range of thermoplastic materials used in the industry.

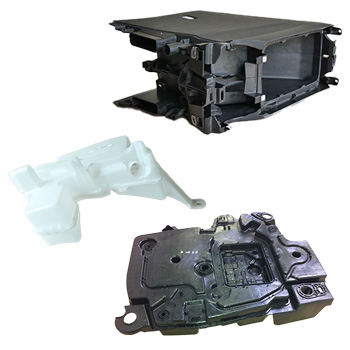

Examples of automotive parts that can be welded by ultrasonic:

- Battery casings, battery blocks (ventilation/breathing components)

- Cooling system components (coolant valves…)

- Brake valves

- Sensor and control housings (temperature sensors, pressure sensors…)

For example, ultrasonic welding can be used to weld cooling valves designed for optimal fluid flow regulation in the cooling circuit, enabling better thermal management of the battery.

Infrared welding

Infrared welding is particularly suitable for plastics and composites, offering a contactless welding method. It provides clean welding (without particles and burrs) even for parts made of fiber-reinforced materials. The fluids used require technical plastics to which infrared welding is perfectly adapted.

This process is ideal for complex multi-path assemblies on technical materials with or without inner wall crossings, as well as components in battery cooling systems or electric motors.

Our infrared welding technology enables to create 3D joint drawings.

Examples of parts that can be welded by infrared:

- Cooling system components

- Propulsion system components

- Glycol-water valves

- Tanks

- Battery modules

Hot plate welding

Hot plate welding is used to produce strong, leak-proof plastic assemblies with complex geometries. It is a robust, viable, and technically strong assembly process used to assemble batteries, fuel tanks, fluid reservoirs, rear light lenses, and other applications where strong joints are essential.

It is perfectly suited for multi-path and profiled parts.

Examples of electric car parts that can be welded by hot plate:

- Cooling system components

- Battery casings

- Fluid tanks

- Air ducts

Spin welding

Spin welding is an effective method of joining parts with circular joint planes.

It is particularly useful for joining components such as air or water ducts in electric motor cooling systems.

This welding process generates frictional heat, allowing homogeneous fusion of the materials for a strong and durable joint, essential for keeping the integrity of the cooling system.

Examples of automative parts that can be spin welded:

- Battery casings (cover)

- Air ducts

- Sensor and control casings (temperature sensors, pressure sensors…)

Laser welding

The main features of laser welding are its precision and its ability to target very specific weld areas without affecting the surrounding materials and avoiding the creation of dust particles.

In the manufacture of electric motors, it can be used to join sensitive electrical components, connectors and parts of the motor housing, providing joints with high mechanical strength and excellent sealing properties.

Examples of parts that can be welded by laser:

- Battery casing

- Electric motor components (stators, rotors, casing)

- Transmission components (gears, shafts)

- Braking system components (brake calipers and discs)

All our welding technologies offer significant advantages in terms of assembly quality, production efficiency, and component durability. They are crucial for meeting the high performance, reliability, and longevity requirements of batteries and electric motors in the automotive industry.

The technology best suited to your needs will always be chosen.

SONIMAT offers you its expertise in automotive welding of thermoplastic parts (for electric vehicles, but not only!). Discover our welding technologies and welded parts on our dedicated page.