- Home

- >

- Fabrics

- >

- Technologies

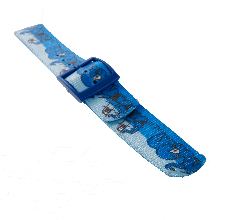

Ultrasonic cutting & welding for Fabrics

- Company

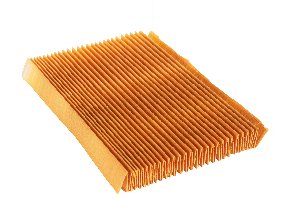

- Composites

- Fabrics

- Food-industry

- Food-industry

- Technical center

- Products

- Technologies

- Technologies

- Ultrasonic slicing

- Packaging

- Plastics

- Metal

- Metal

- Product

- Product

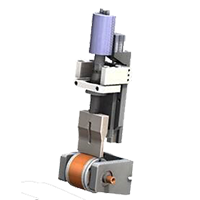

- metal welding machine

- Technology

- Technology

- Ultrasonic metal welding

- News

- News

- News

- Shows and events

- Downloads

- Contact