- Home

- >

- Composites

- >

- Products

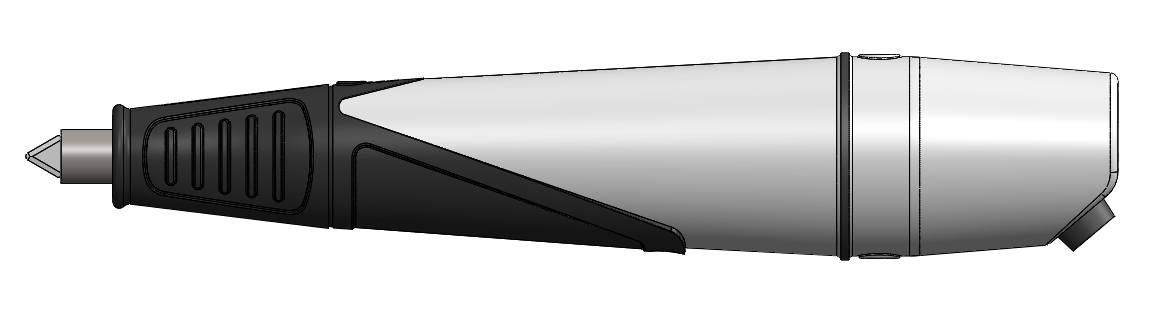

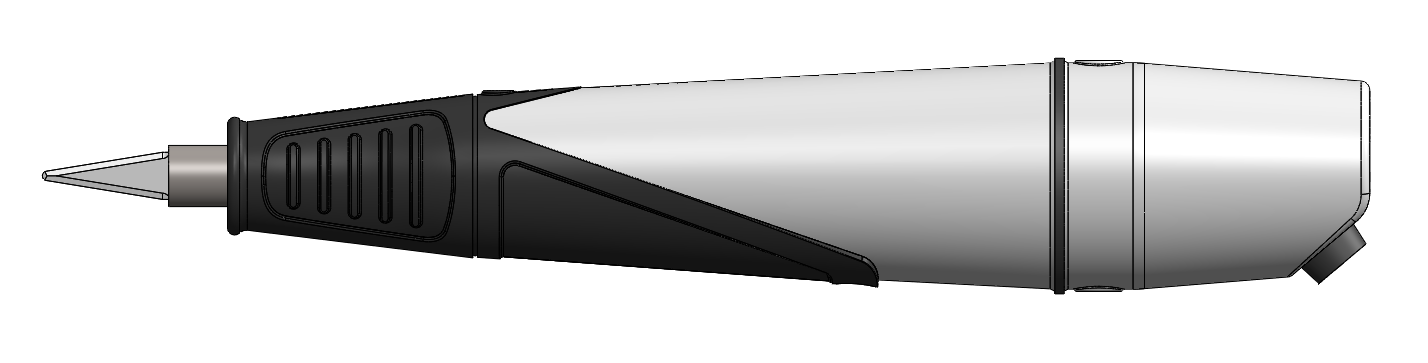

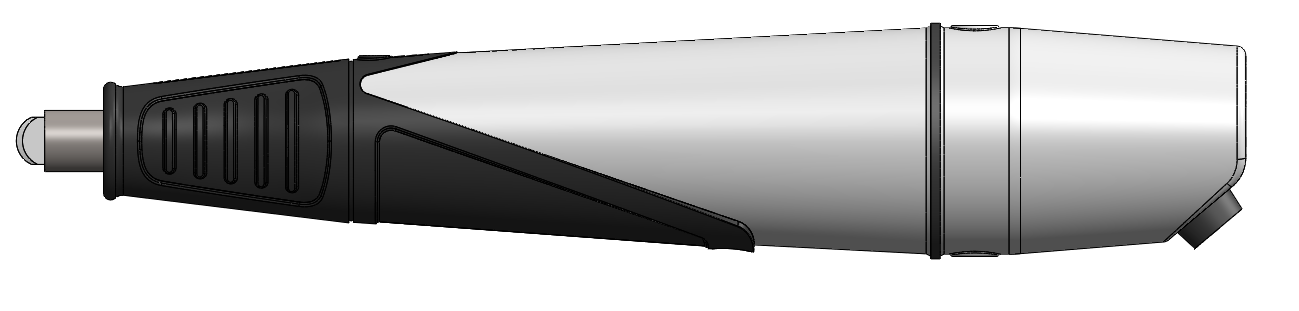

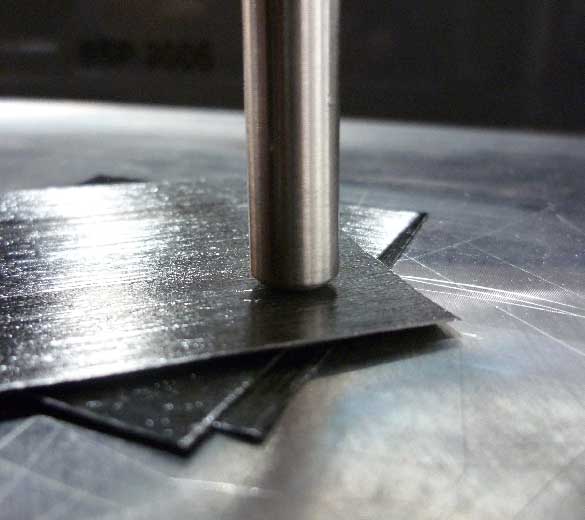

SSP – Ultrasonic composite cutter & welding system

- Company

- Composites

- Fabrics

- Food-industry

- Food-industry

- Technical center

- Products

- Technologies

- Technologies

- Ultrasonic slicing

- Packaging

- Plastics

- Metal

- Metal

- Product

- Product

- metal welding machine

- Technology

- Technology

- Ultrasonic metal welding

- News

- News

- News

- Shows and events

- Downloads

- Contact